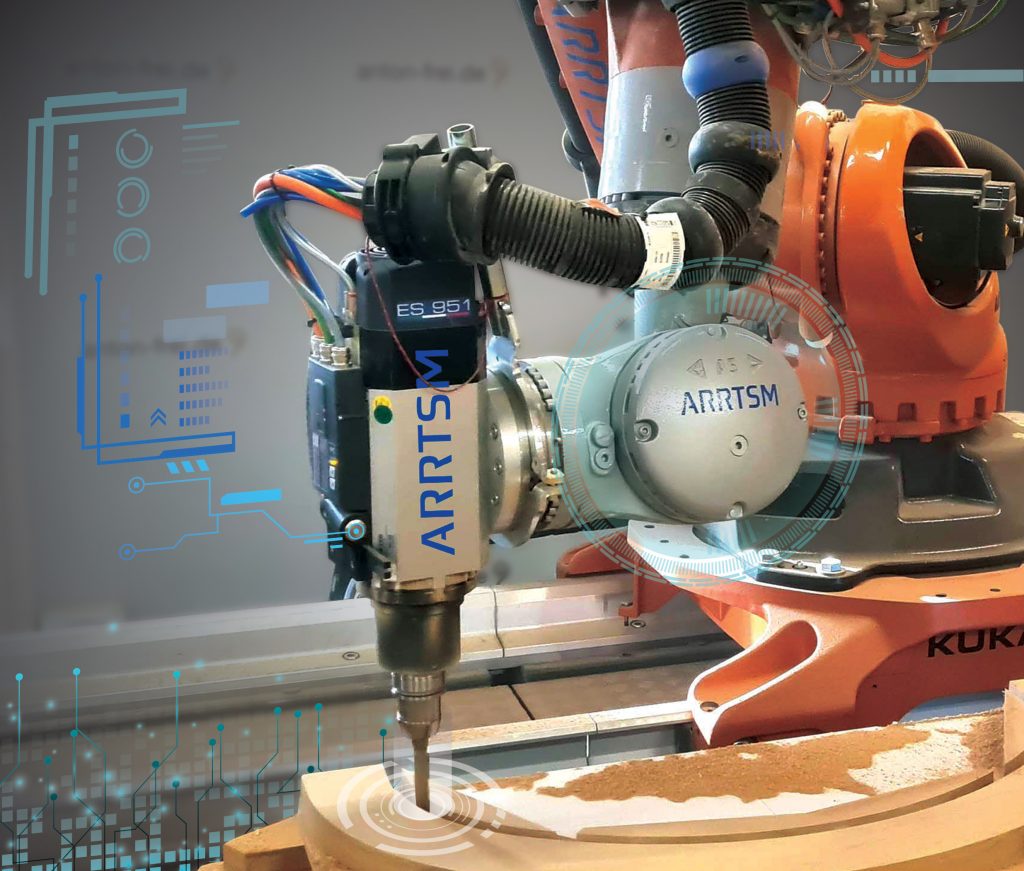

Our ARRTSM software functions as a powerful tool in the transition from design to fabrication, seamlessly bringing concepts to life. The process begins with a 2D or 3D CAD drawing, which serves as a digital blueprint for the piece to be created.

When the design is ready, the CAD file is imported into our advanced software system. Our technology recognizes and interprets the geometric data from the drawing. Depending on the complexity of the design, the software might create a series of machine operations to produce the piece, or it might intelligently delegate different tasks to various machines.

Once the design is finalized, our system generates machine codes or instructions tailored to our robotic technology. These instructions guide the machines through the precise cutting, shaping, and finishing processes required to produce the piece.

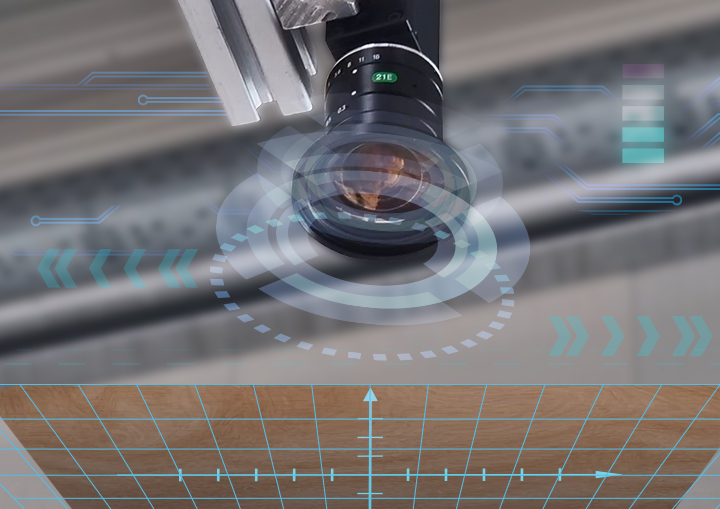

AI plays a crucial role in our autonomous robotic digital factories. It enables robots and other machines to make intelligent decisions and adapt to changing conditions. AI algorithms are used for tasks like machine learning, computer vision, predictive maintenance, and optimization of production processes.

Automatic selection of tools and machining parameters, generation of robotic-code from CAD data considering the condition of the raw material and the robot system

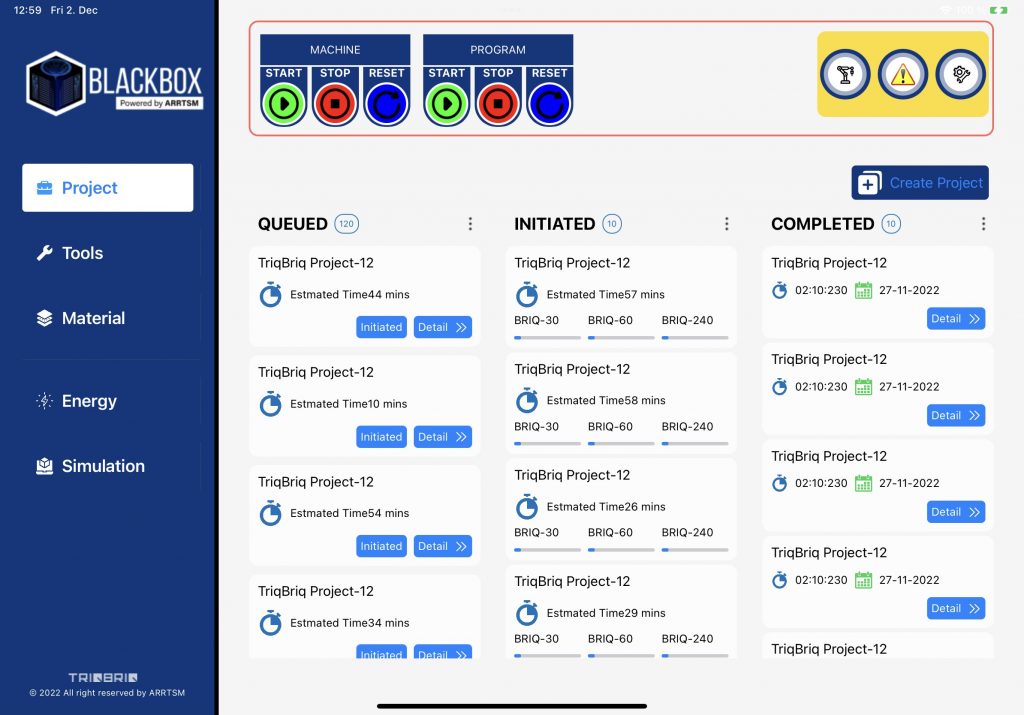

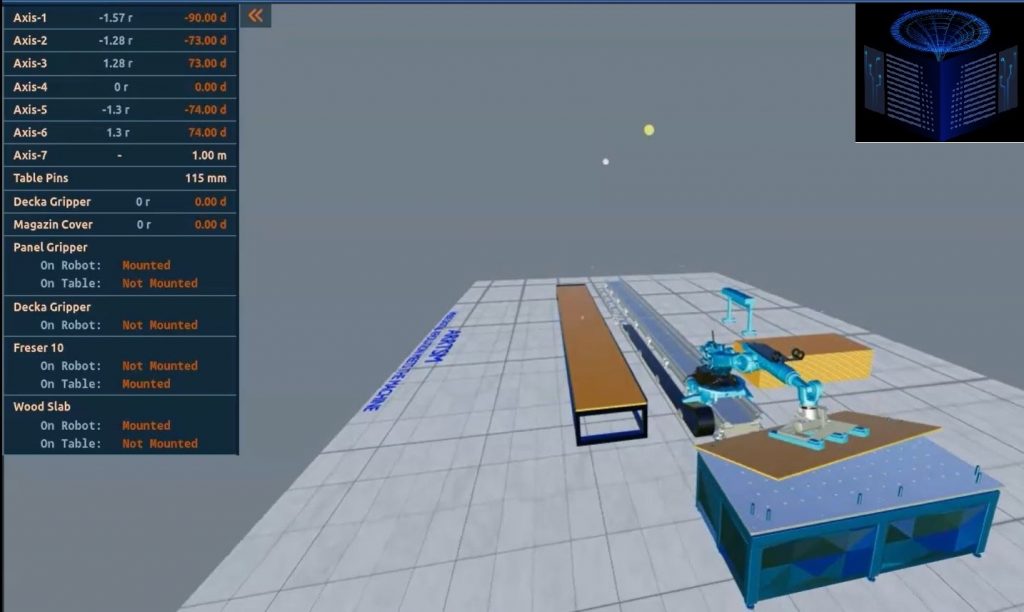

ARRTSM Digital Twin with a look-ahead function and real-time simulation driven by AI combines several powerful technologies to create a highly advanced and responsive system. Including real-time process and system simulation and algorithms for collision prediction

Our Digital Twin represents a virtual replica of the autonomous digital Factory, process representing the complete system. It incorporates real-time data from the physical counterpart, such as sensors, IoT devices, manufacturing data, to create a synchronized virtual model.

Industrial image processing, also known as machine vision, is a field that involves the use of computer vision and image processing techniques for automation and quality control in industrial environment. It involves capturing 2d or 3d images and analyzing images or videos of product in real time, processes, or components to extract valuable 2d or 3d information from the given product and make decision based on the detected information from the object to be processed.

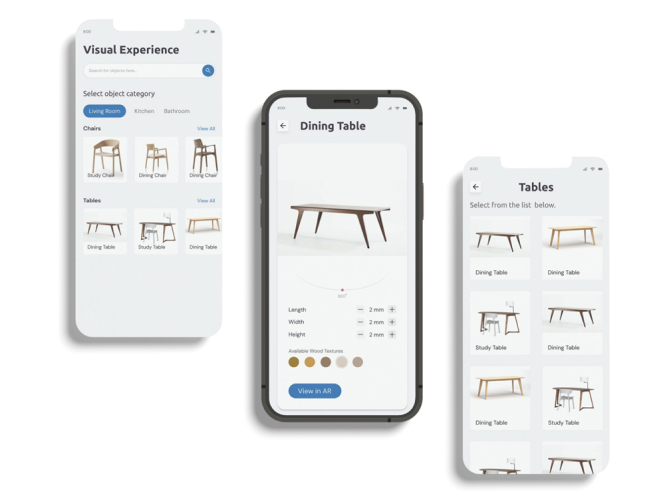

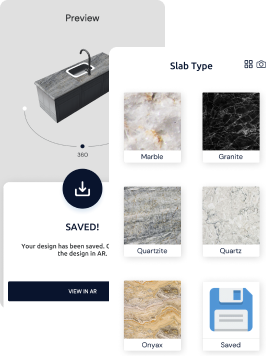

The Lucy APP offers customers an innovative user interface for defining the workpiece characteristics such as size, configuration and features. The application transmits the Data to our Software.

The Lucy Stone App offers you an innovative user interface for defining the workpiece characteristics such as size, configuration and features. The application enables you to design you Countertop, Table, Stairs and so on

Unlock convenience and efficiency with our app’s powerful features.

ARRTSM Augmented Reality projects the end products 1:1 with the highest Information density, animated Representations of planned or already existing wood, stone, plastic products. AR applications can also be used as a tool for interactive serve to plan the interior design and playfully help the customer’s imagination

AR applications can also be used as a tool for interactive serve to plan the interior design and playfully help the customer’s imagination

ARRTSM Inc.

300 Delaware Ave. Suite 210 #390

Wilmington, DE 19801

United States of America

© 2016-2023 ARRTSM | All Rights Reserved